A simple brine mixer

BRIMAX 350

- For small batches of 50 to 350 litres - Integrated pump - Homogeneity of the brine produced in the mixing result - Push-button control - Option: funnel for ingredients

Brine control station

BRIMAX 1000 = No ice in the brine

- Standardised brine preparation - Automatic brine mixing system for batches of 150 l to 1,000 l. - Operation via touch panel - Ongoing process monitoring by operator - Active cooling with heat exchanger - Communication with other tanks and the connector - Modular construction enables up to 5 vessels to be connected to one controller - Options: pump, agitator blades, wash down nozzles

Brine preparation line

Main advantages

Precise brine dosing, recipe standardisation, modular and linear design, fast mixing and cooling of components, from clear brine to highly viscous brine, maintenance of stable temperature, high hygiene standard, simple user level operation

Massagers and

Injectors

JBT@SCHROEDER

Large mixer

BRIMAX 2000

- Brine mixer for batches up to 2000 l. - Functionally and optionally identical to the BRIMAX 1000

Universal injectors

IMAX 300 / 400 / 600SL

- 350 / 420 / 620 (conveyor width) - 1000 - 6.200 kg/h (capacity) - 50 - 255 (number of needles depending on model) - Needle exit sequentially for pitted products - Options: - Tenderizer - Brine container (on trolley) or FT130 or UWF250

Red meat injector

IMAX 420 / 520 / 620

- Conveyor with walking beam - 420 / 520 / 620 mm Conveyor width - 1.500 - 10.000 kg/h capacity - Models from 123 and up to 610 needles - Full range of options

Poultry and fish injector

IMAX 430 / 630 / 930

- Belt conveyor - 420 / 620 / 920mm Belt width - Capacity 1000-10000 kg/h - From 205 to 900 needles - Full set of options

IMAX „P“- Especially for Poultry

IMAX 600 / 900P

- 630 / 930 mm conveyor belt width - 9,000 kg/h capacity - One head with 343 or 511 needles (900P) - High capacity when processing chicken breasts, legs, wings, etc. - Limitations in options and settings

HVB Technology (high viscosity brine)

The best known application is meat injection

Addition of trimmings from fish, meat or poultry to utilise their natural function as protein, special components for injecting brines with high viscosity for better cut preparation and final yield, improved flavour, reduced cost of production, reduced cleaning, process optimisation for use of residual products, additional possibilities for creating new products, clean label

Meat trolley:

UWF250

brine container:

F

T

130/200

/

LB350:

Brine filtration

All types of filtration are multistage

Proper brine filtration ensures equal injection speed, high accuracy and better brine quality Diverse solutions for all kinds of needs, depending on the type of brine, operating time, percentage of injection, type of raw material

Mechanical processing of meat products by rolling, pressing and/or tenderizing

PREMAX series, main advantages

- Higher yield, smaller brine pockets, better brine distribution, better protein extraction, better cohesion of the different parts of the meat after cooking, quality processing of the muscle mass for softer parts of the meat, time saving massaging etc.

Roller Tenderiser

MacMAX 500

- Two 79 blade rollers - Capacity between 2,000 and 10,000 kg - Perfect surface finish - Robust design - Improved protein extraction - Improved cohesion between the different parts of the meat after cooking - Improved results for slicing and cooking

Roller press

PSM 650

- Two 250 mm diameter rollers for strong press effect - 2,000 - 10,000 kg capacity - Enhanced processing of the muscle structure for more flexible parts of the meat - Greater productivity - Time-saving massage/tumbling

Needle Tenderizer

TMAX 620

- Up to 600 softening needles - Up to 10,000 kg/h capacity - Injector-like design - Option: retraction for bone retraction - Increased cutting capacity - Reduced brine pockets - Better brine distribution

Massagers

MAX series, main advantages

Higher loading capacity - 85% vs. 50%, up to 50% shorter processing time, automatic loading at the front and unloading at the back for better product flow and hygiene, controlled cooling down to 2 °C, intensive protein activation, improved muscle and intramuscular cross-section bonding, lower protein abrasion on the product surface (due to active jacket cooling), increased water retention water retention, imparting tenderness and a more stable structure in the final product

Compact series

MAX 600

- Charging up to 600 kg - Vacuum up to 50 mbar possible - Temperature at least 2 °C "MAX600 with integrated vacuum and cooling unit - Cooling jacket/thermowell - Different blade designs available - Highest cutting and cooking performance

Compact series

MAX 1200

- Loading up to 1200 kg - Vacuum up to 50 mbar possible - Temperature at least 2 °C "MAX1200 with integrated vacuum and connection to an external cooling unit - Cooling jacket/thermowell - Different blade designs available - Highest cutting and cooking performance

Industrial series

MAX 2500 / 3000 / 6000

- Capacity 2.500 / 3.000 / 6.000 kg - Up to 5 MAX massagers can be charged via one large vacuum charging container - In-line design - All possible options - Best equipment for massaging / tumbling products after injection - Maximum yield when preparing and slicing

Stuffing for whole meat

HAMAX

- The only adjustable length syringe on the market - Stuffed bars - 6-8 sec interval - Can work with the automatic clipper - Reduction in clipping losses by up to 50% - Casing compression up to 30% - Various magazine diameters and filling tubes - Combination with SVU6800 possible

Complete line solutions

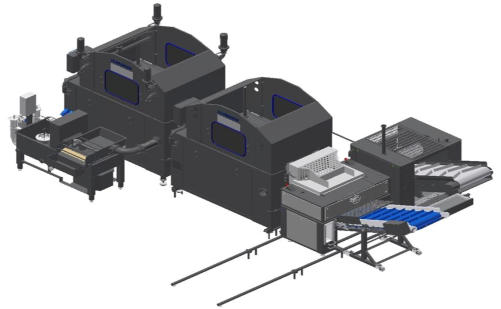

PROMAX

- Fully automated and controlled process from start to finish - Rapid offloading of the MAX massager production line - Reduced labour costs - Highest degree of automation in the loading and unloading process

Conveyor system

FlowMAX

- Process speed depends on product consistency - Time-efficient "unloading" of the MAX production line - Reduces labour costs - Highest degree of automation in the "loading and unloading" process

Conveyor

FlowMAX Z-Style

- Continuous feed through 600 kg hopper charge - Saves labour - Less time needed to fill the injector - Injector speed can be adjusted to the injector cycle/min. - An integrated pump guides the brine back into the injector

Drip Tumbler

DT 2500

- Used for back bacon, chicken parts on the bone, whole chicken - Removes surface brine from products after injection = send the "dry" product into the IQF freezer compartment. - Tumbling effect after injection - An integrated pump guides the brine back into the injector

Vibrating table

VT 2500

- "Drying" the various parts of the meat before being fed to the IQF freezer / breading line - Continuous removal of surface brine after injection - Suitable for small pieces such as chicken wings, chicken breasts... - Integrated pump directs the brine back into the injector

IMA

X

Z-Con

v

ey

or

S

teaker

T-

M

A

X

Stand-alone equipment

Processing lines

Combined solutions

IMA

X

M

A

X

S

uction

conta

ine

r

FlowMA

X

IMA

X

V

ibra

tion

VISMA

X

IMA

X

Z-Con

v

ey

or

IMA

X

MacMA

X

Operating software for the visualisation process

VISMAX

- Intuitive operation - Identical interface for all machines - Simple operation for all SCHRÖDER machines - Overview of all machines on the production line - Shows the actual machine settings and data - Recipe management - Management service shows service requirement and operating hours - Installed on a standalone PC and available for all popular mobile devices - Suitable for all SCHRÖDER equipment with STP 104 panel (BRIMAX, IMAX and MAX)

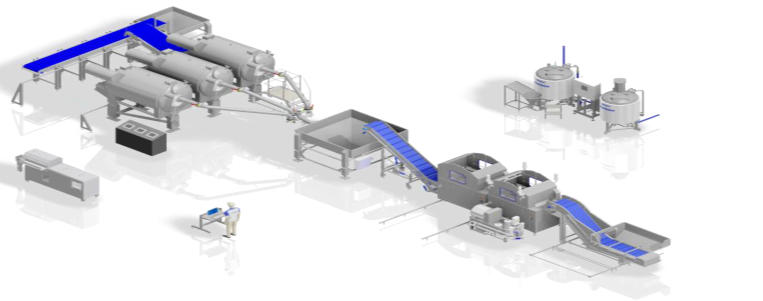

Brine preparation line

Main advantages

Precise brine dosing, recipe standardisation, modular and linear design, fast mixing and cooling of components, from clear brine to highly viscous brine, maintenance of stable temperature, high hygiene standard, simple user level operationОперационное программное

обеспечение для процесса

визуализации VISMAX

• Интуитивное управление • Одинаковый интерфейс для всех машин • Простое управление для всех машин SCHRÖDER • Возможность обзора всех машин производственной линии • Показывает фактические настройки и данные машины • Управление рецептами • Сервис управления показывает потребность в сервисе и рабочее время • Устанавливается на отдельном ПК и доступен для всех распространенных мобильных устройств • Применяется для всего оборудования SCHRÖDER с панелью STP 104 (BRIMAX, IMAX и MAX)

Heading Text

Операционное программное

обеспечение

• Интуитивное управление • Одинаковый интерфейс для всех машин • Простое управление для всех машин SCHRÖDER

LONG HEADING TEXT

0091/28190221

Dolor proident aute lorem laboris

cillum! Cupidatat incididunt.

Schmitt

LONG HEADING TEXT

Consectetur velit qui tempor veniam cupidatat minim nulla pariatur ad in dolor et dolor ea sed enim. In adipisicing quis sit ex velit lorem. Ut nostrud voluptate in ipsum deserunt adipisicing duis non anim in. Voluptate tempor ut. Nisi ipsum, consequat velit laboris ea. Reprehenderit ea id. Dolore laboris ut qui amet? Sunt est sit consequat adipisicing commodo elit anim.

Ursa TS

- Pos 1

- index-en

- index-de

- jbt tipper tie-ru

- jbt tipper tie-de

- jbt tipper tie-en

- jbt schroeder-ru

- jbt schroeder-de

- jbt schroeder-en

- jbt consumables-ru

- jbt consumables-de

- jbt consumables-en

- schreyer-ru

- schreyer-de

- schreyer-en

- Kutter Alpina Swooper SWV200-S

- Kutter KuG Wetter 120 STL

- Kolbenfuehler REX RKF130

- Doppelclipautomat TT18-15

- Poekelinjector Schroeder IMAX 300SL

- impressum-ru

- impressum-de

- impressum-en

- datenschutz-ru

- datenschutz-de

- datenschutz-en